Industrial Labels & Nameplates

Specialize in all aspects of harsh environment electronics manufacturing.

Your nameplates and labels are a vital extension of your brand’s identity.

That’s why we offer durable nameplate designs and industrial labeling solutions that embody the care and pride you invest in your products. Expertly crafted, our labels are built to withstand harsh environments and are designed to last 10–20 years, ensuring your brand stands the test of time.

Products

Through our partnership with New Process Corp, a jointly owned company with locations in Fort Wayne, IN, and Sidney, OH, Riverside provides comprehensive solutions for all your industrial printing needs.

Dimensional Emblems

- Kromex

- ABS Chrome & Dome

- Doming

Labels

- ANSI Safety

- Product Identi cations

- Graphics & Decals

- Prime labels

Graphic Overlays

- Functional & Illuminated

- Dead-Front

- Dial Faces

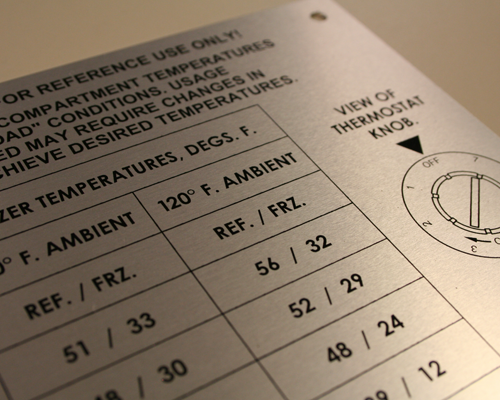

Nameplates

- Metal

- Metalphoto

- Graphics

Custom Products

Customization Choices

Our durable nameplates and labels are designed for indoor and outdoor applications and can withstand harsh conditions, including exposure to chemicals. We offer printing on metals and polymers, using standard colors, custom-matched colors, or specialty inks to meet your specific requirements.

- 6 SMT Line Across 2 Riverside Facilities

3D SPI – Solder Paste Inspection

3D SPI – Solder Paste Inspection

- 3D paste inspector done before placing components

- Effectively eliminates critical challenges of shadowing and specular reflections that other 3D inspection solutions fail to address.

Solder Paste Screen Printer

Solder Paste Screen Printer

- 7-second cycle time

- Adjustable stencil rails with automatic motorized adjustments for quick and easy changeovers

3D AOI – Automated Optical Inspection

3D AOI – Automated Optical Inspection

- Solder, part markings and polarity inspection

- Placement inspection for precise component alignment

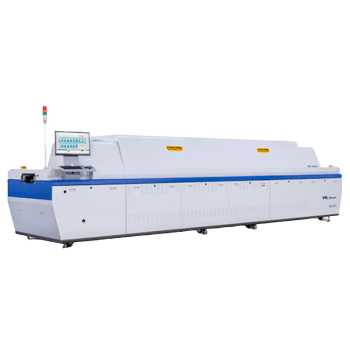

Reflow Oven

Reflow Oven

- Temperature profile memory for each product

- No time loss when switching production models, eliminating the need for separate profile checks

Bare Board Loader

Bare Board Loader

- Magazine changeover time of less than 26 seconds

- Capacity of up to 5 racks

Pick N’ Place Machines

Pick N’ Place Machines

- Maximum speed of 100,000 CPH

- Precision accuracy of ±22 μm @ cpk ≥ 1.0

- Flexible production capabilities

- Wide system design with broad compatibility for components and versatile PCB applications

- Additional Electrical Assembly Equipment

Dage Sub-Micro Systems Model X

Dage Sub-Micro Systems Model X

- Offers extremely high-resolution measurement capabilities for precise inspection and testing at the sub-micron scale.

- Ensures stable, repeatable positioning and alignment for consistent and reliable test results.

- Accommodates a wide variety of samples and materials, making it suitable for diverse electronics and semiconductor testing scenarios.

Ersa Versaflow 40-50 1-Phase Selective Solder

Ersa Versaflow 40-50 1-Phase Selective Solder

- Customizable for various production needs with simultaneous soldering processes.

- Advanced nozzle and flux systems ensure accuracy on complex PCBs.

- Real-time monitoring for consistent quality and minimal defects

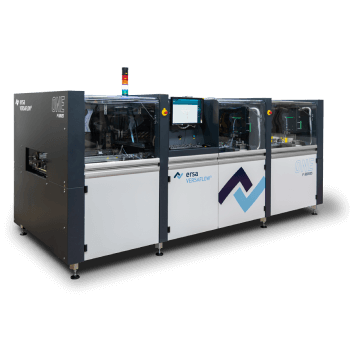

Ersa Versaflow 2-Phase Selective Solder

Ersa Versaflow 2-Phase Selective Solder

- Simultaneous soldering capability boosts efficiency for higher throughput.

- Space-saving layout ideal for smaller production environments without compromising performance.

- Advanced flux application and nozzle technology ensure accurate soldering with minimal defects.

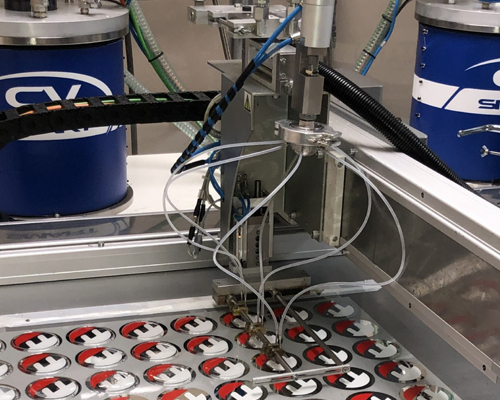

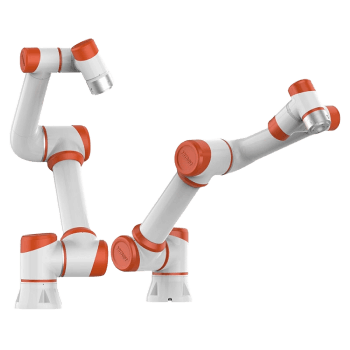

S922 Hitbot Potting Robots

S922 Hitbot Potting Robots

- Delivers accurate, consistent potting and adhesive application across various component sizes.

- Offers intuitive controls and easily customizable parameters for different production requirements.

- Engineered for continuous, stable performance in demanding industrial environments.

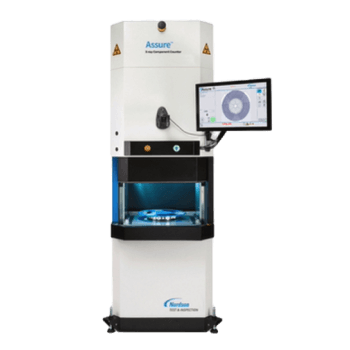

Assure Pro X-Ray Component Counter

Assure Pro X-Ray Component Counter

- Utilizes advanced X-ray technology to count components on reels with exceptional speed and precision.

- Supports a variety of reel sizes and component types, including ultra-small chips.

- Integrates with ERP/MRP systems to provide up-to-date inventory data and reduce material shortages

Delta 8 Coating/Dispensing System

Delta 8 Coating/Dispensing System

- Supports various applications, including conformal coating, precision dispensing, and potting, tailored for various production needs.

- Features a high-precision gantry system for accurate and repeatable material application.

- Real-time monitoring ensures consistent results and maintains quality across all operations